Veterinary Autoclave Troubleshooting Guide

In the fast-paced environment of a veterinary clinic, the autoclave is the unsung hero. When it works, surgical packs are sterile and ready for the next spay or dental. When it doesn't? Your entire schedule grinds to a halt.

Here is a guide to the most common autoclave headaches and how to fix them before they disrupt your day.

1. The Temperature Just Won’t Rise

If your unit is stuck in a preheat loop or isn’t hitting the required 121°C (250°F), you aren’t just losing time—you’re compromising sterility.

The Culprit: Often, this is a water level issue. If the reservoir is low, the heating element can't generate enough steam.

Check This: Ensure you are using distilled water only. Tap water can cause mineral buildup (scale) on heating elements, acting as insulation that prevents heat transfer.

The Fix: Clean the heating element with a specialized autoclave cleaner and ensure the water sensor is free of debris.

2. The Infamous "Wet Pack."

You open the door, and the surgical wraps are damp. In the veterinary world, a wet pack is one that is contaminated.

The Culprit: This is usually a loading error. If packs are stacked too tightly or "nestled" together, steam can't circulate, and moisture gets trapped.

Check This: Is your chamber filter clogged? If the air-jet or drain filter is blocked with lint or hair (a common vet clinic reality!), the vacuum/drying phase will fail.

The Fix: Use a rack to separate pouches. Ensure paper-plastic pouches are placed on their sides (like files in a folder) rather than flat.

3. Steam Leaking from the Door

If you hear a "hissing" sound or see steam escaping around the front of the machine, your cycle will likely fail due to pressure loss.

The Culprit: The door gasket (the rubber ring) is likely worn, dry, or dirty.

Check This: Look for small cracks or bits of surgical tape stuck to the gasket. Even a tiny piece of debris can break the seal.

The Fix: Wipe the gasket daily with a damp, lint-free cloth. If it’s cracked, it’s time to order a replacement.

4. "Error Code XXX."

Modern autoclaves are smart—sometimes too smart. They’ll throw a code like "E001" or "Cycle Aborted" and refuse to move.

The Culprit: This could be anything from a power surge to a faulty solenoid valve.

The Fix: Don’t guess. Every brand has a specific "Error Code Table." Below, I’ve provided a way to get the answer instantly.

The Autoclave "Power Prompt"

If your autoclave is acting up and the manual is nowhere to be found, use this prompt with an AI assistant to get a specialized diagnosis.

Copy and paste the text below, filling in the bracketed information:

"I am a veterinary professional troubleshooting an autoclave. The brand is [Insert Brand, e.g., Midmark, Tuttnauer, Ritz] and the model is [Insert Model Number].

The specific issue I am seeing is: [Describe the problem, e.g., Error Code E007 / Water leaking from bottom / Cycle won't start].

Based on the manufacturer’s service manual for this specific model, can you tell me:

What are the most likely causes for this specific error?

What are the 'first-step' fixes I can do in the clinic?

At what point do I need to stop and call a professional technician?"

Pro-Tip: The "Golden Rule" of Autoclaves

90% of autoclave failures in vet clinics are caused by two things: Poor water quality and hair/lint buildup. A weekly cleaning routine can save you thousands in repair bills.

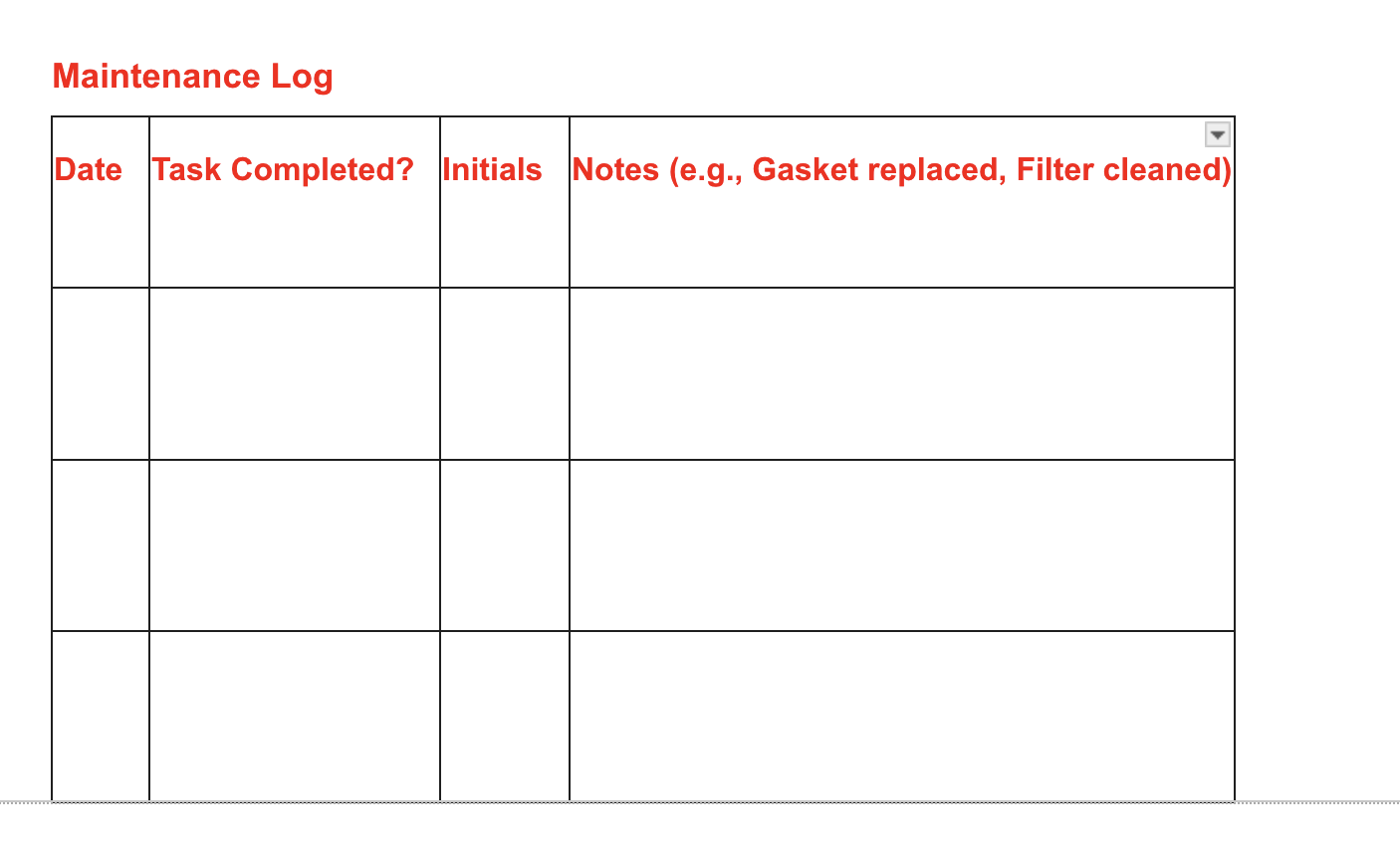

Since many autoclave issues in a veterinary clinic stem from hair, dander, and mineral buildup, a consistent maintenance schedule is the best defense.

Here is a printable-style Weekly Maintenance Checklist you can post in your sterilization area.

🏥 Veterinary Autoclave: Weekly Maintenance Checklist

Goal: Prevent "Error Codes," "Wet Packs," and heating element failure.

✅ Monday: The Deep Clean

Drain the Reservoir: Empty all water from the reservoir. Stagnant water grows biofilm and concentrates minerals.

Chamber Scrub: Use a non-chlorinated, manufacturer-approved cleaner (like Omni-Cleaner or Speed-Clean). Scrub the bottom of the chamber to remove any "cooked-on" debris or surgical tape residue.

Rinse & Refill: Rinse the chamber thoroughly with distilled water and refill the reservoir to the "Full" line.

✅ Wednesday: The "Seal & Filter" Check

Gasket Inspection: Wipe the door gasket with a damp, lint-free cloth. Look for cracks, pits, or any pet hair that might break the vacuum seal.

Clean the Chamber Filter: Locate the small mesh filter at the bottom or back of the chamber. Remove it and rinse away any lint or hair.

Tip: If this is clogged, your packs will stay wet!

✅ Friday: The Performance Test

Biological Indicator (BI) Test: Run a spore test to ensure the autoclave is actually killing microorganisms, not just getting hot. Log the results in your clinic’s sterilization binder.

Tray & Rack Check: Remove the trays and the wire rack. Wipe them down to prevent oxidation (rust) from forming, which can transfer to your stainless steel instruments.

🚫 The "Never" List (Post this for new staff!)

NEVER use tap water. It will ruin the heating elements within weeks.

NEVER use steel wool or wire brushes to clean the chamber (it causes pitting and rust).

NEVER overload the trays. If steam can't circulate, the center of the pack isn't sterile.

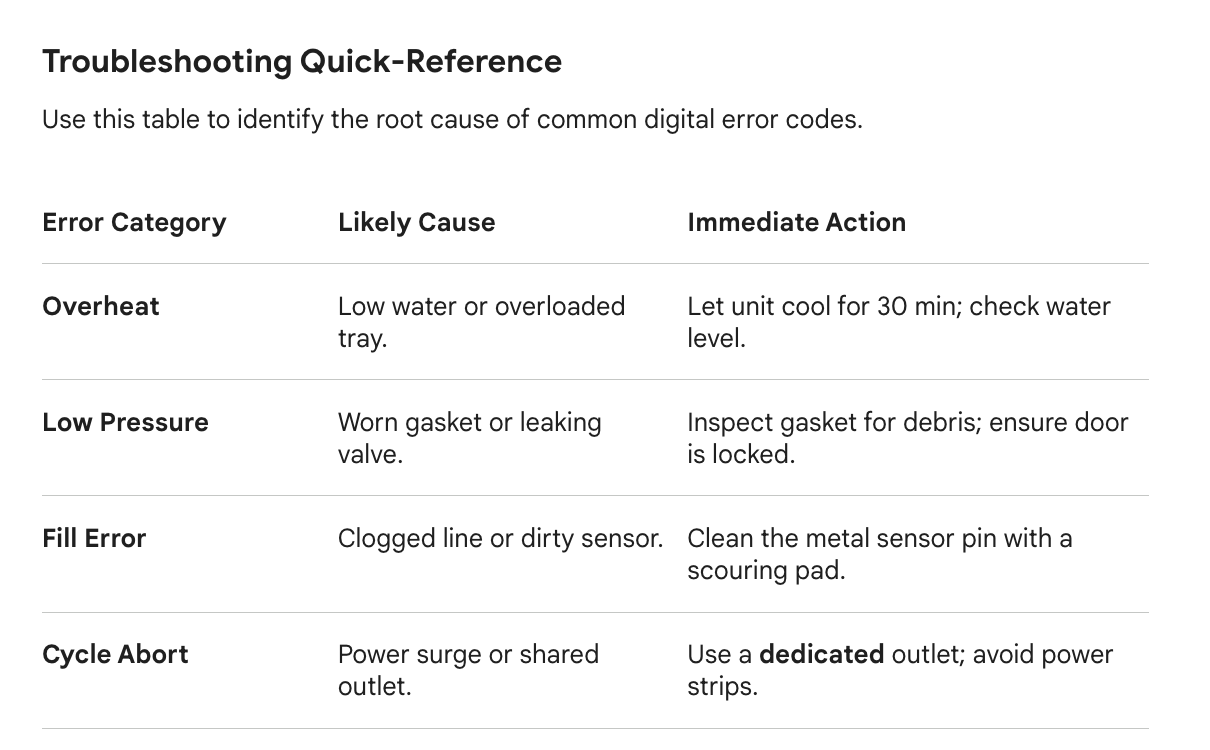

Since different brands use different codes (for example, a "C-001" on one machine might be an "E-003" on another), I’ve designed this Troubleshooting Quick-Reference by "Error Type."

This makes it easy for your staff to identify the root cause based on what the machine is doing or saying.

⚡ Autoclave Troubleshooting Quick-Reference

Keep this near the autoclave for immediate diagnosis.

Common Error Categories

Error Type

Common Codes (Varies)

Probable Cause

Immediate Action

Overheat

E001, E1, Hi-Temp

Low water, overloaded chamber, or faulty sensor.

Vent steam, let the unit cool for 30 min, and check the water level.

Low Pressure

E002, P-Low, Vac-Fail

Worn door gasket or leaking safety valve.

Inspect the gasket for debris; ensure the door is locked tight.

Fill Error

E003, No-Water

Clogged water line or dirty water sensor.

Clean the sensor (the small metal pin) with a scouring pad.

Cycle Abort

E007, Power-Fail

Power surge or unstable voltage.

Plug the unit into a dedicated outlet (no power strips!).

Dry Failure

Wet Pack, E009

Clogged chamber filter or poor loading.

Clean the filter mesh; reload packs on their sides.

The "3-Step Rescue" Protocol

If an error occurs mid-cycle, follow these steps immediately:

Safety First: Do not attempt to force the door open if the pressure gauge is above zero.

The "Hard Reset": Many software glitches can be cleared by turning the power switch OFF for 60 seconds and then back ON.

Check the "Big Three":

Is it Distilled Water?

Is the Gasket clean?

Is the Filter clear of hair/lint?

When to Call for Service 📞

If you see these "Red Flag" issues, stop using the machine and call a technician:

Burning smell: Indicates a short circuit or a fried heating element.

Constant Hissing: Even after cleaning the gasket, steam continues to escape.

Water Under the Unit: A sign of a blown internal hose or a failing weld.

Customizing This for Your Clinic

To make this perfectly accurate for your team, you can look up the "Error Code Table" in your manual and jot down the most common ones here:

Code ______: Meaning: ____________________________________

Code ______: Meaning: ____________________________________

Selecting and Using a Veterinary Autoclave

Autoclaves for veterinary use are a key piece of equipment for sterilizing surgical (and dental) tools and packs, gowns, drapes, and items for wound care and other procedures such as Penrose drain.

Outside of vet med, autoclaves are also used at human hospitals, tattoo parlors, research facilities, and various other businesses that require sterile equipment.

Although different models of autoclaves serve a similar purpose, there is variation when it comes to which type of autoclave best meets the needs of a specific veterinary hospital. Here are some things to consider when purchasing or upgrading…

Veterinary Autoclave Automation: Is Manual or Automatic Better?

Autoclave technology—particularly, automatic versus manual operation—is a hotly debated topic. There’s no right or wrong answer, but rather individual preference based on knowing the pros and cons of each.

Supporters of manual-function autoclaves claim they break down less often. Thus, they don’t incur the inconvenience and expense of frequent repairs. And despite the technology being older, many vets can easily have valves and seals replaced or repaired.

The downside is that manual machines require more time and attention from staff. Team members must do things by hand rather than using a “set it and forget it” button. This takes time away from patient-care tasks. It can even lead to a safety concern in some cases if the machine is ignored while running.

Many practices love automatic autoclaves for their simplicity and ease of use. Team members can just select a setting, then leave the machine to complete the cycle without any intervention. This saves time and prevents user errors, especially when the practice is busy.

However, the high temperatures and moisture of the autoclave can be detrimental to the electronic components of automatic machines. And electronic parts might be more difficult to replace or repair when compared with basic components like seals. Thus, some veterinarians have complained that this newer technology breaks down more often.

Factors When Selecting an Autoclave for Veterinary Use

In addition to the automatic versus manual question, here are some considerations…

New or Used. Some veterinarians and practice managers prefer to buy new equipment that comes with a longer warranty, and perhaps even a maintenance and repair plan. A good quality used or refurbished model might make sense for some hospitals, though. Veterinary autoclaves can last a long time (some have been known to keep going 20+ years!), so both new and used can potentially be a great investment.

Specific Functions and Guidelines. See which cycles and functions can be performed on your machine—such as wrapped and unwrapped packs, gowns and fabrics, liquids, rubber/plastic, etc.—and how long each will take. Make sure it covers everything you might possibly need to autoclave and works fast enough for your needs.

Autoclave Size. Practice pace and number of surgeries per day or per week generally determine the size of autoclave that is needed. To ensure you’re comparing apples to apples when price shopping, and that you find something specific to your clinic’s needs, look at the machine’s…

Chamber size (volume and dimensions).

Tray size and capacity (some have multiple rows of trays to maximize capacity).

How many standard packs or cassettes can be sterilized at a time?

How much space does it take up on the countertop?

Machine Maintenance and Repairs. Planning ahead can help ensure that ongoing autoclave operation is as smooth as possible. Prior to your purchase, ask questions about how to maintain the machine. For example, how often should it be cleaned in-hospital, and is there a special cleaning solution required?

Also, think about who will be repairing it and how long it takes for repairs/receiving replacement parts.

Is there a warranty in place? What about a 24/7 technical helpline? How much do repairs typically cost, and will you be given a loaner machine in the meantime?

Some vets choose to get in touch with a local repair person who’s not associated with the autoclave’s manufacturer or distributor. Developing a relationship with a local human hospital could be a way to get in touch with a local repair person.

Confirming Sterilization. It’s important to ensure your machine is effectively sterilizing your tools, even if it appears to be running smoothly. Always check your state’s minimum guidelines. Here are some common ways to monitor your machine’s effectiveness…

Indicator tape is the first line, with a color change to indicate the machine got hot. However, it’s not necessarily an accurate indicator of sterilization.

Indicator strips are also crucial, as they are a more accurate indicator of sterilization especially inside of a pack.

More and more veterinary practices are also routinely testing with biological indicators, confirming that the machine could effectively kill certain microorganisms.

Where to Find a Veterinary Autoclave Supplier or Get Recommendations

Checking colleagues’ recommendations is a great way to get helpful information and narrow down your choices. Talk face-to-face, look at forums on VIN, or check online reviews.

Also, check with your local distributors and sales reps to see what’s available. If they’ve sold autoclaves to local practices, ask for a referral to see how other practices like their equipment.

The decision will probably be a balance of cost, user-friendliness, maintenance considerations, functions/settings, size, and reviews from colleagues. These factors can help ensure your practice gets the best value to help facilitate daily practice flow, maximize patient care, and minimize headaches.

Written by: Dr. Tammy Powell, DVM